The Simplest Things! - Designing Seed, Grain Cleaning or Food Processing Plants

It’s quite interesting that the simplest things in mechanization and automation are often overlooked but are really what make systems perform!

When a new seed, grain cleaning or food processing plant is being designed, there are many things to consider and incorporate into the drawings early in the process.

How we are going to sample and audit the product and the various fractions separated, at each stage of the process flow should be and needs to be one of those things prioritized.

You can have the best equipment available, super operators and awesome conveyance, but if it isn’t easy or possible to see the results of the adjustments and changes made to all the pieces of equipment in the line up, your investment isn’t going to perform as well as it should.

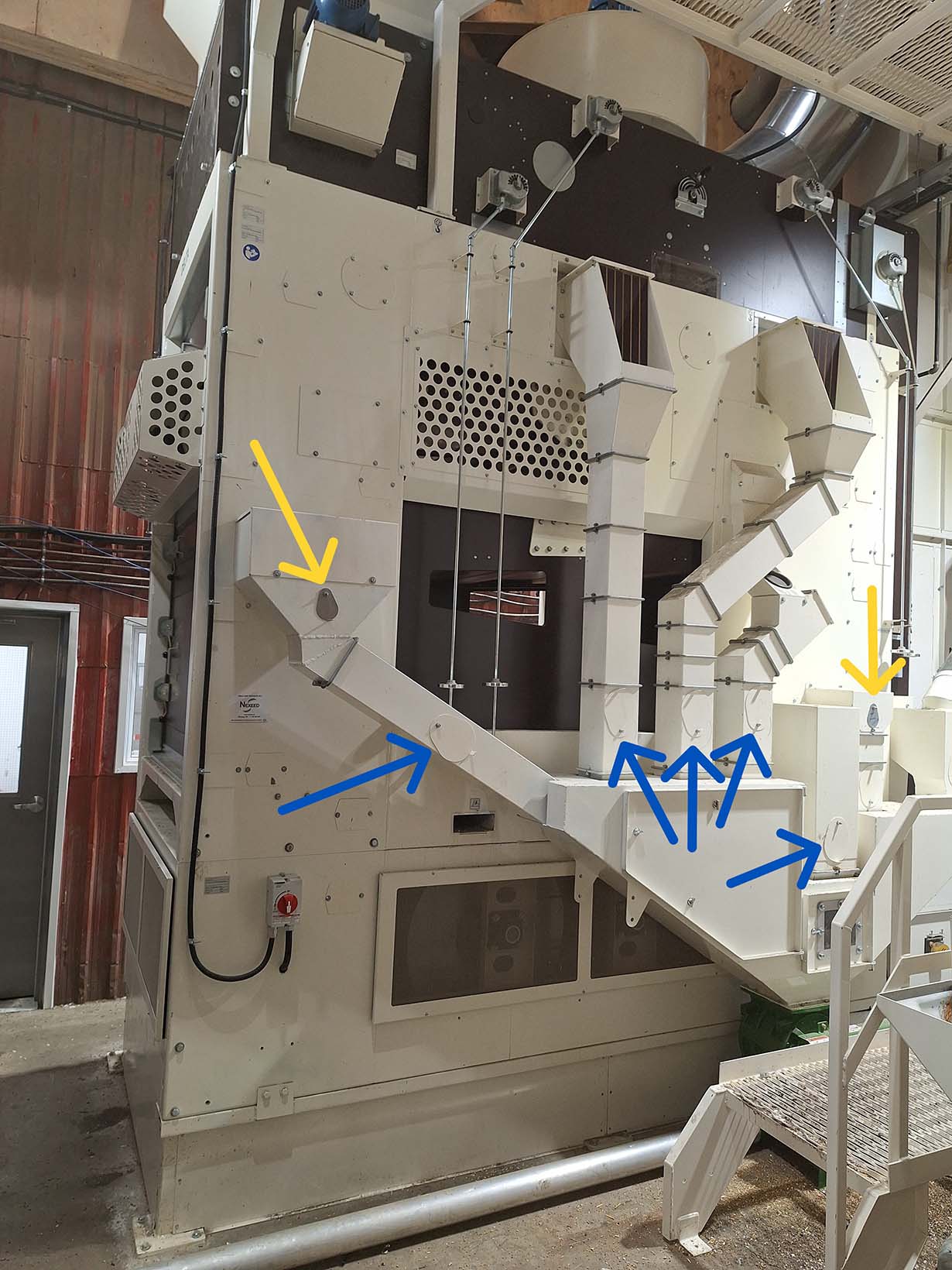

Here is a pic of a Cimbria Delta 107 Screen cleaner showing the sample ports, both small for a sampling tool and large for inserting your hand to collect a large sample fast.

The Blue Arrows point to large sample ports where it is safe to insert your hand and the Yellow arrows port to small sample ports where there is risk of pinching a finger or two, where the small Cimbria supplied sample tool should be used safely.

The picture below shows what the soybean samples taken from the cleaner look like in each separated fraction.

The factory supplied sample ports on the Delta clear keep the operators safe while making it easy for them to insure their adjustments made to the cleaner result in the desired outcomes.

However, most equipment in the line up does not come with the safe sample ports, so discussions between the millwrights and draftsman, and equipment providers will need to happen to determine the best place, number and size of sample ports.

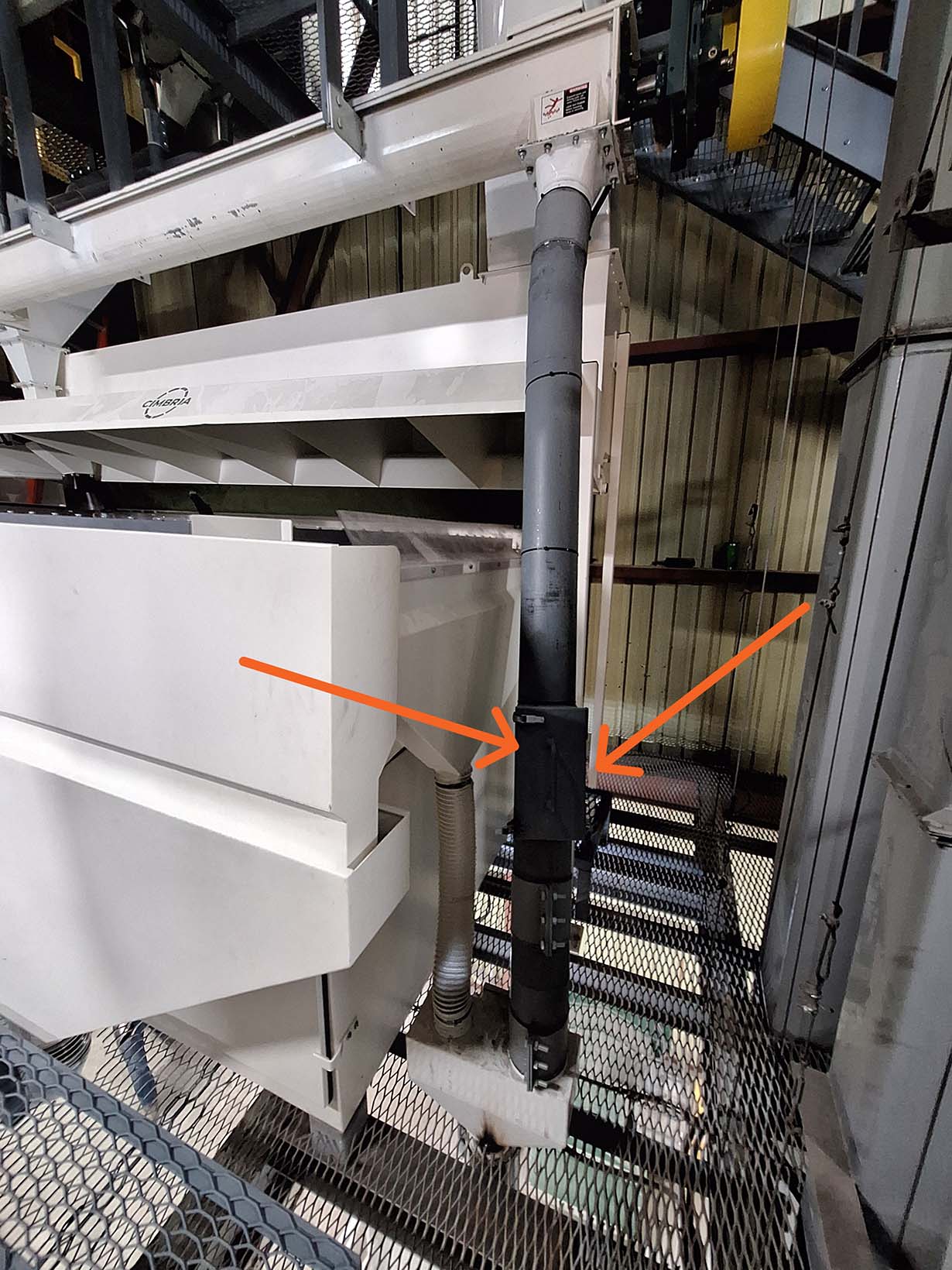

Here are two pics of a thoughtfully placed rejects test port below a bank of Profile Spirals. It is at chest height, safe, and large enough to put an extra-large gloved hand in to capture a sample. It is also directly beside the outlets of a gravity table, so the operator can watch two operations at once! You can see by the sample that the spirals are currently set too aggressively and need to be slowed down to keep more good beans out of the rejects.

If this test port was not readily available, chances are the operator, (myself in this case) would not have made this important small but necessary adjustment.

Sample test ports should be easy to reach, in a well-lit area, close to the controls of the machines, and preferably on the same level, if it is in a multi level facility to save shoe leather.

Care should be taken when designing the ports so they are self cleaning, not on the “wear side” of spouting, do not have sharp edges and will seal up when closed for good house keeping and instilling product integrity when closed.

Here is a video showing the sample coming off a Cimbria Delta 107, top screen scalping discharge.

Don’t let your sample ports be an after thought and crammed in at the last moment. These simple things are where you measure the efficiency and productivity of your investment.

If your team is in the market to upgrade or build a new plant, feel free to simply reach out to us at Nexeed to insure your endeavors will be successful.

We’ve been there, sampled that!